Quality Assurance

System construction

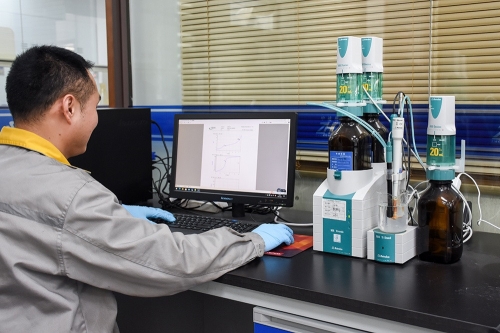

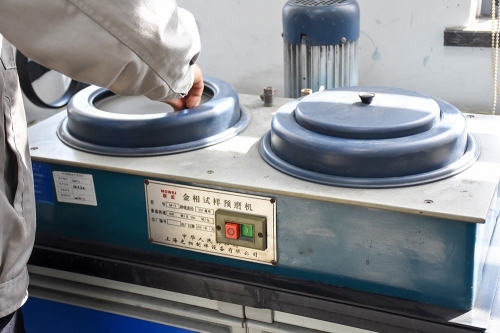

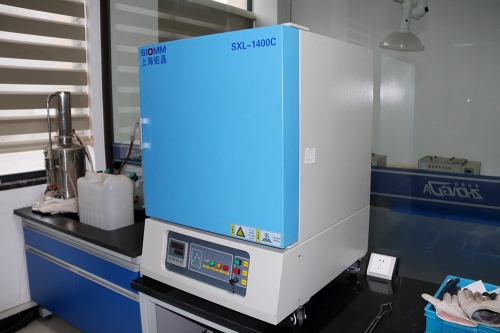

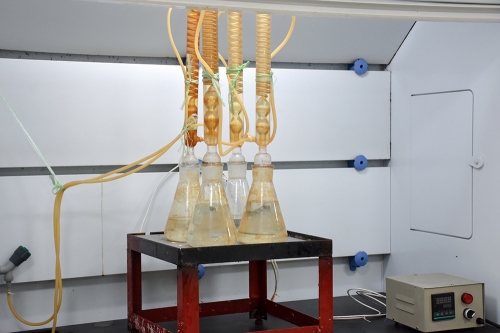

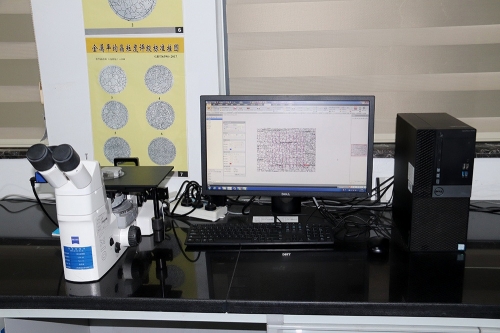

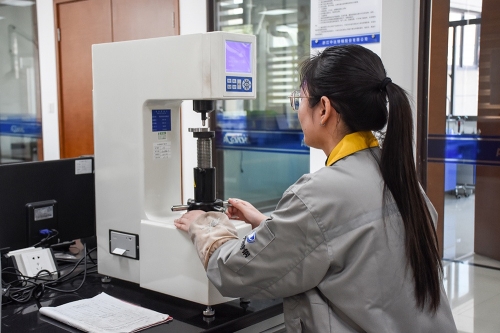

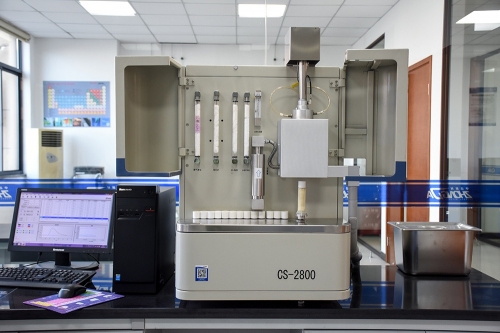

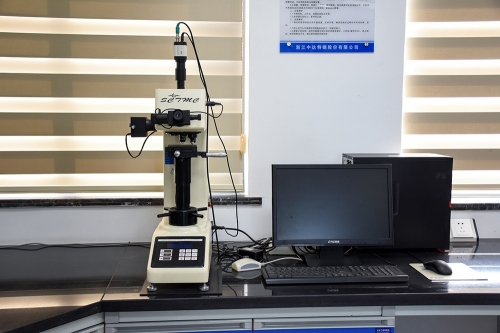

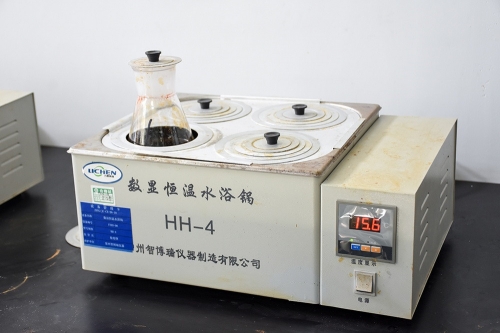

Testing Equipment

The test center has direct reading spectrometer (SPECTROMAXx), hydraulic universal test machine, microcomputercontrol electronic universal test machine (GNT200), impact test bench, Roche hardness meter, several small load Breitbarthardness meter, gold phase microscope (Cai's), crystal corrosion device, covering seamless steel pipe products chemicalcomposition analysis, stretching, impact, hardness, a total of 14 projects involving national standards and U.S. standardshave been recognized in the product rational performance. Precision to meet the user's reality and potential needs.

Technological innovation has always been the foothold of Zhongda Advanced Material for development. Throughtechnology introduction, technology development, technical equipment and process improvement.